ERP Cost Optimization: 7 Proven Strategies to Slash Expenses

Want to cut costs without cutting corners? ERP cost optimization is your golden ticket. By fine-tuning your ERP system, you can unlock serious savings, boost efficiency, and future-proof your business—all without sacrificing performance.

Understanding ERP Cost Optimization

Enterprise Resource Planning (ERP) systems are the backbone of modern businesses, integrating core functions like finance, HR, supply chain, and operations into one unified platform. However, these powerful tools come with a price tag—both upfront and ongoing. ERP cost optimization refers to the strategic process of reducing total ownership costs while maximizing the system’s value and performance.

It’s not just about cutting budgets; it’s about making smarter investments. Whether you’re running SAP, Oracle, Microsoft Dynamics, or a cloud-based solution like NetSuite, understanding where costs accumulate is the first step toward meaningful savings.

What Is ERP and Why Costs Add Up

ERP systems centralize data and streamline workflows across departments. But their complexity often leads to hidden or underestimated expenses. Implementation alone can cost millions for large enterprises, and ongoing maintenance, licensing, upgrades, and training continue to drain budgets.

According to Gartner, over 70% of ERP projects exceed their initial budget due to scope creep, poor planning, or underestimating integration needs. This makes ERP cost optimization not just beneficial—but essential.

- Licensing fees (per user, module, or tier)

- Implementation and customization costs

- Infrastructure (on-premise vs. cloud)

- Ongoing support and maintenance

- Training and change management

The True Cost of Inaction

Ignoring ERP cost optimization can lead to bloated budgets, underutilized features, and operational inefficiencies. Many companies pay for modules they don’t use or maintain legacy systems that slow down innovation.

“Organizations that fail to optimize their ERP spend often end up with redundant processes, data silos, and missed ROI.” — ERP Analyst, Panorama Consulting

Worse, outdated or poorly managed ERP systems can hinder scalability, making it harder to adapt to market changes or regulatory demands.

Strategy 1: Right-Size Your ERP Licensing

One of the most impactful ways to achieve ERP cost optimization is by aligning your licensing model with actual user needs. Too often, companies over-provision licenses, paying for full-access users when limited or self-service access would suffice.

For example, not every employee needs a full ERP license. Roles like warehouse staff or field technicians might only require access to specific modules or mobile interfaces. By switching to named user, concurrent user, or role-based licensing, you can significantly reduce costs.

Identify Underutilized Licenses

Start by auditing your current user base. Use system logs and analytics to determine who’s actively using the ERP and which modules they access. You may discover that 30–40% of users rarely log in or only use basic functions.

Tools like SAP GRC or third-party analytics platforms can help track usage patterns and flag inactive accounts. Once identified, downgrade or remove unnecessary licenses.

- Conduct quarterly license audits

- Use role-based access control (RBAC)

- Implement license reclamation policies

Negotiate Better Licensing Terms

Vendors often offer flexible pricing models, especially for long-term contracts or bulk purchases. Don’t accept the first quote—negotiate. Ask for discounts on multi-year agreements, bundled modules, or educational/non-profit rates if applicable.

For cloud ERP systems like Oracle Cloud or Microsoft Dynamics 365, consider pay-as-you-go or subscription models that scale with your business. This avoids overcommitting to capacity you don’t yet need.

“Companies that renegotiate ERP contracts every 3–5 years save an average of 18% on annual licensing costs.” — TechValidate Survey

Strategy 2: Optimize ERP Implementation Costs

Implementation is often the largest single expense in an ERP lifecycle. Poor planning, scope creep, and reliance on expensive consultants can balloon budgets. ERP cost optimization starts long before go-live—with smart project management.

A well-structured implementation plan reduces risks, accelerates timelines, and minimizes costly rework. Whether you’re deploying a new system or upgrading an existing one, controlling implementation costs is critical.

Choose the Right Deployment Model

The decision between on-premise, cloud, and hybrid ERP directly impacts cost. On-premise systems require significant upfront investment in hardware, software, and IT staff. Cloud ERP, on the other hand, shifts costs to a predictable subscription model with lower initial outlay.

According to IDC, cloud ERP adoption grew by 17% in 2023, driven by lower TCO (Total Cost of Ownership) and faster deployment.

- Cloud: Lower upfront cost, faster ROI, scalable

- On-premise: More control, higher long-term maintenance

- Hybrid: Best of both worlds for complex environments

Limit Customization and Scope Creep

While customization can enhance functionality, it also increases complexity, testing time, and future upgrade costs. Every custom module or integration must be maintained, which adds to long-term expenses.

ERP cost optimization means resisting the urge to over-customize. Instead, configure the system using built-in tools and standard workflows. If customization is necessary, prioritize only mission-critical changes and document them thoroughly.

“For every dollar spent on customization, companies spend two dollars maintaining it over five years.” — Nucleus Research

Strategy 3: Leverage Cloud ERP for Scalability and Savings

Migrating to a cloud-based ERP system is one of the most effective ERP cost optimization moves. Cloud ERP eliminates the need for physical servers, reduces IT staffing demands, and offers automatic updates and backups.

erp cost optimization – Erp cost optimization menjadi aspek penting yang dibahas di sini.

Providers like Oracle ERP Cloud, Microsoft Dynamics 365, and NetSuite offer subscription-based pricing that scales with your business, making it easier to manage cash flow.

Reduce Infrastructure and Maintenance Costs

On-premise ERP systems require servers, cooling, power, security, and dedicated IT staff. These hidden costs can account for up to 40% of total ERP spending over five years.

Cloud ERP shifts these responsibilities to the vendor. You pay a fixed monthly fee, and the provider handles maintenance, security patches, and disaster recovery. This not only reduces costs but also improves system reliability and uptime.

- No need for server rooms or hardware upgrades

- Automatic software updates included

- Reduced need for in-house ERP administrators

Scale Flexibly with Business Needs

Cloud ERP allows you to add or remove users, modules, and storage as your business evolves. Seasonal businesses, for example, can scale up during peak periods and scale down afterward—paying only for what they use.

This flexibility prevents over-investment in capacity and supports agile growth. It’s especially beneficial for mid-sized companies expanding into new markets or launching new product lines.

“Cloud ERP customers report 30% faster time-to-value compared to on-premise deployments.” — Aberdeen Group

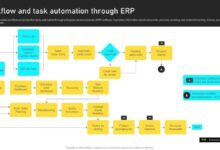

Strategy 4: Automate Processes to Reduce Labor Costs

One of the core promises of ERP is automation—and when used effectively, it’s a powerful tool for ERP cost optimization. Manual data entry, paper-based approvals, and redundant workflows eat up employee time and increase error rates.

By automating routine tasks like invoice processing, payroll, inventory updates, and report generation, you free up staff for higher-value work and reduce operational costs.

Streamline Financial and Supply Chain Workflows

Finance and supply chain departments are prime candidates for automation. ERP systems can auto-generate purchase orders when inventory hits a threshold, reconcile accounts payable with minimal human intervention, and forecast cash flow using real-time data.

For example, a manufacturer using automated procurement in their ERP reduced order processing time by 65% and cut procurement staff hours by 40%.

- Automate invoice matching and approvals

- Use predictive analytics for inventory management

- Integrate with e-procurement platforms

Reduce Human Error and Rework

Manual processes are prone to errors—duplicate entries, incorrect pricing, missed deadlines. These mistakes lead to rework, compliance issues, and customer dissatisfaction.

Automation ensures consistency and accuracy. For instance, an ERP system can validate data in real-time, flag discrepancies, and enforce approval workflows. This reduces audit risks and lowers the cost of compliance.

“Companies that automate 70%+ of their ERP workflows see a 50% reduction in processing errors.” — Deloitte Insights

Strategy 5: Optimize ERP Maintenance and Support

After implementation, maintenance and support become recurring expenses. Annual maintenance fees typically range from 15% to 22% of the initial software license cost. While necessary, these costs can be optimized.

Many organizations overpay for support packages that include services they don’t use. Others rely too heavily on vendor support, incurring high hourly rates for routine tasks.

Review and Renegotiate Support Contracts

Don’t automatically renew your ERP support contract. Evaluate whether you’re getting value for money. Ask: Are you using all the included services? Can internal teams handle basic troubleshooting?

Consider switching to third-party support providers like Rimini Street, which offer up to 50% savings on SAP and Oracle support. These providers deliver the same patches and updates without the premium price tag.

- Audit support usage quarterly

- Compare vendor vs. third-party support costs

- Negotiate service-level agreements (SLAs)

Build Internal ERP Expertise

Investing in internal training reduces dependency on external consultants. Train super users in each department to handle common issues, perform basic configurations, and train new employees.

This not only cuts support costs but also improves user adoption and system utilization. A knowledgeable team can identify optimization opportunities faster and respond to issues without delays.

“Organizations with certified ERP super users reduce external support costs by 35% on average.” — Panorama Consulting Report

Strategy 6: Integrate ERP with Complementary Tools

ERP systems don’t operate in isolation. Integrating them with CRM, HRIS, e-commerce platforms, and BI tools enhances functionality and eliminates data silos. But poor integration can lead to inefficiencies and hidden costs.

ERP cost optimization includes ensuring seamless, low-maintenance integrations that deliver real value.

Use Pre-Built Connectors and APIs

Custom integration development is expensive and fragile. Whenever possible, use pre-built connectors or APIs provided by the ERP vendor or third parties.

erp cost optimization – Erp cost optimization menjadi aspek penting yang dibahas di sini.

For example, Microsoft Dynamics 365 offers native integrations with Power BI, Azure, and Office 365. NetSuite provides SuiteApps for quick integration with Shopify, Salesforce, and Amazon.

- Pre-built connectors reduce development time

- APIs enable real-time data sync

- Lower risk of integration failures

Avoid Data Redundancy and Manual Transfers

When systems aren’t integrated, employees often re-enter data manually—wasting time and increasing errors. This redundancy inflates labor costs and undermines data integrity.

Proper integration ensures that sales orders in CRM automatically create invoices in ERP, or that time tracking in HRIS feeds directly into payroll. This end-to-end automation is a cornerstone of ERP cost optimization.

“Companies with fully integrated ERP ecosystems report 25% higher operational efficiency.” — McKinsey & Company

Strategy 7: Continuously Monitor and Improve ERP Performance

ERP cost optimization isn’t a one-time project—it’s an ongoing discipline. Systems evolve, business needs change, and new technologies emerge. Regular monitoring ensures your ERP continues to deliver value at the lowest possible cost.

Establish KPIs, conduct periodic audits, and foster a culture of continuous improvement.

Track Key Performance Indicators (KPIs)

Measure what matters: user adoption rates, process cycle times, system uptime, support ticket volume, and ROI per module. These metrics reveal inefficiencies and guide optimization efforts.

For example, low user adoption in a module might indicate poor training or unnecessary complexity—both of which increase costs.

- Monthly system usage reports

- Cost per transaction analysis

- ROI tracking by department

Conduct Regular ERP Health Checks

Just like a car needs tune-ups, your ERP system needs periodic health checks. These assessments evaluate performance, security, compliance, and optimization opportunities.

Many ERP vendors offer health check services, or you can use third-party consultants. The insights gained can prevent costly outages, identify underused features, and recommend upgrades or consolidations.

“Organizations that perform annual ERP health checks avoid 60% of major system failures.” — Gartner Research

What is ERP cost optimization?

ERP cost optimization is the strategic process of reducing the total cost of owning and operating an Enterprise Resource Planning system while maximizing its efficiency, functionality, and return on investment. It involves evaluating licensing, implementation, maintenance, and usage to eliminate waste and improve value.

How can I reduce my ERP licensing costs?

You can reduce ERP licensing costs by auditing user activity, downgrading or removing unused licenses, adopting role-based access, and negotiating better terms with vendors. Switching to cloud-based subscription models can also provide more predictable and scalable pricing.

Is cloud ERP cheaper than on-premise?

Generally, yes. Cloud ERP has lower upfront costs, no hardware expenses, and includes maintenance and updates in the subscription fee. While long-term costs may vary, cloud ERP typically offers a lower total cost of ownership (TCO) over 3–5 years, especially for mid-sized businesses.

Can automation really save money in ERP systems?

Absolutely. Automating repetitive tasks like invoice processing, payroll, and inventory management reduces labor costs, minimizes errors, and speeds up operations. Companies that automate 70% or more of their ERP workflows report up to 50% fewer processing errors and significant time savings.

What are the risks of poor ERP cost optimization?

Poor ERP cost optimization can lead to overspending on unused licenses, inefficient processes, high maintenance fees, and low user adoption. It can also result in system downtime, compliance risks, and missed opportunities for growth and innovation.

ERP cost optimization isn’t about cutting corners—it’s about working smarter. By right-sizing licenses, streamlining implementation, leveraging the cloud, automating workflows, and continuously monitoring performance, businesses can dramatically reduce costs while enhancing efficiency and scalability. The strategies outlined here provide a comprehensive roadmap to get the most value from your ERP investment. Start today, and turn your ERP from a cost center into a profit driver.

erp cost optimization – Erp cost optimization menjadi aspek penting yang dibahas di sini.

Further Reading: